Setting the New Standard

In Helmet Technology.

Our dynamic frame mixed with our dual-stage liner has been designed to have a low centre of mass, and fits closely to the head to promote the ideal environment to absorb impact energy, and be maximally efficient when it comes to saving your brain.

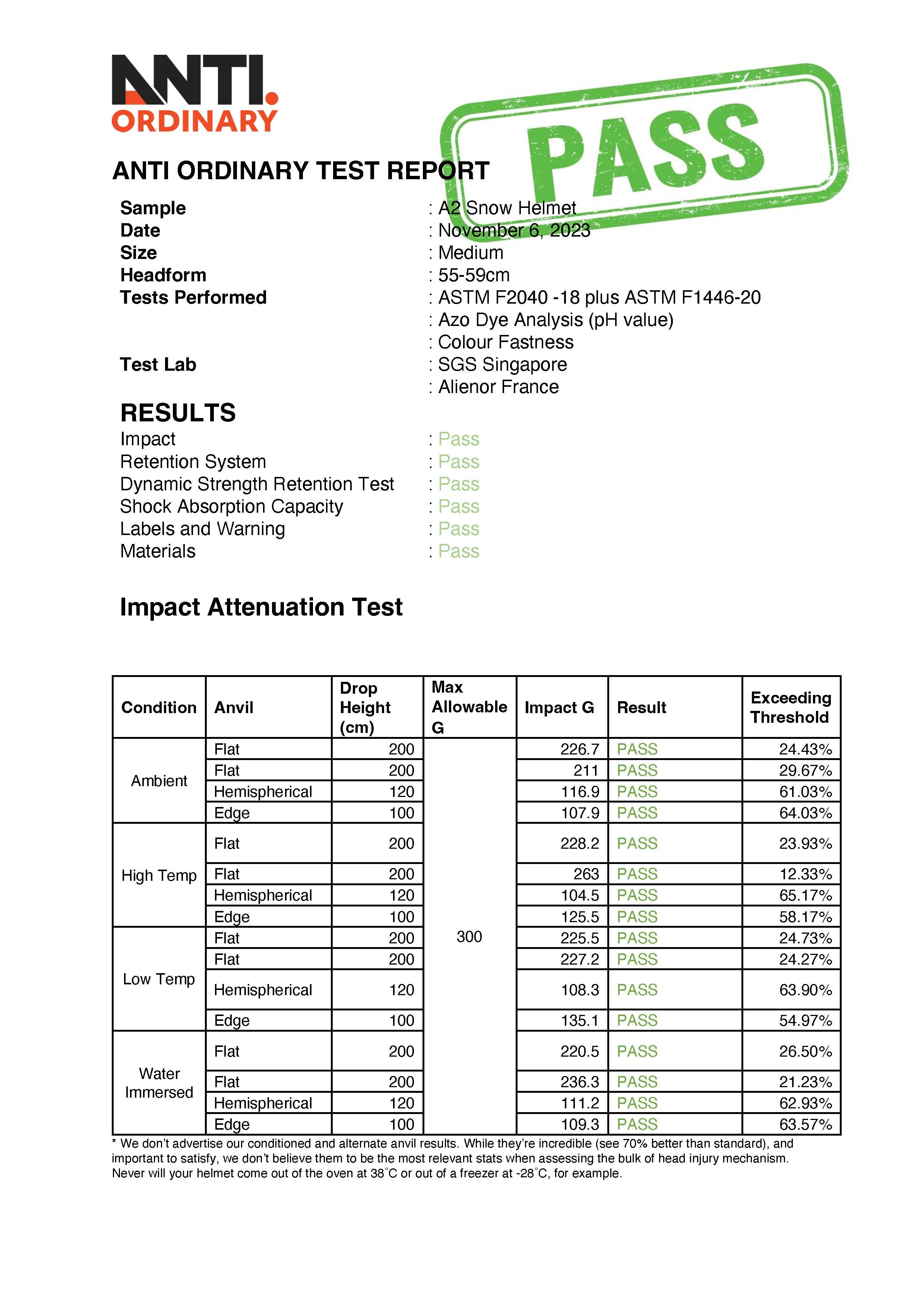

We are certified to both international snow helmet certifications, EN1077 and ASTM F2040. We release our independent safety testing data for these certifications to be fully transparent with how safe our technology really is.

Beyond that, we believe in you having all the information to make the most informed decision for your brain’s safety.

We’re doing what we think every helmet manufacturer must do - but doesn’t.

How did we make a helmet this safe?

It’s a combination of factors all put together into what we call our ‘Dynamic Frame’. It’s taken us 7 years of R&D to perfect this frame, ensuring it can do it all. The fit and feel of the unit is absolutely unmatched; but the real beauty of it is how it can protect you.

The frame itself is comprised of 80+ parts that create a system that can fit, flex and mould to any headshape, while remaining rock solid and impenetrable when you need it the most.

This, most definitely isn’t the cheapest way to build a snow sports helmet. In fact, our helmet costs up to 5x how much it costs to make a traditional helmet.

We think your brain deserves the best, and we don’t cheap out in design, materials or build quality.

Kinda like the Rolls Royce of ski helmets (without the wild price tag).

How it works

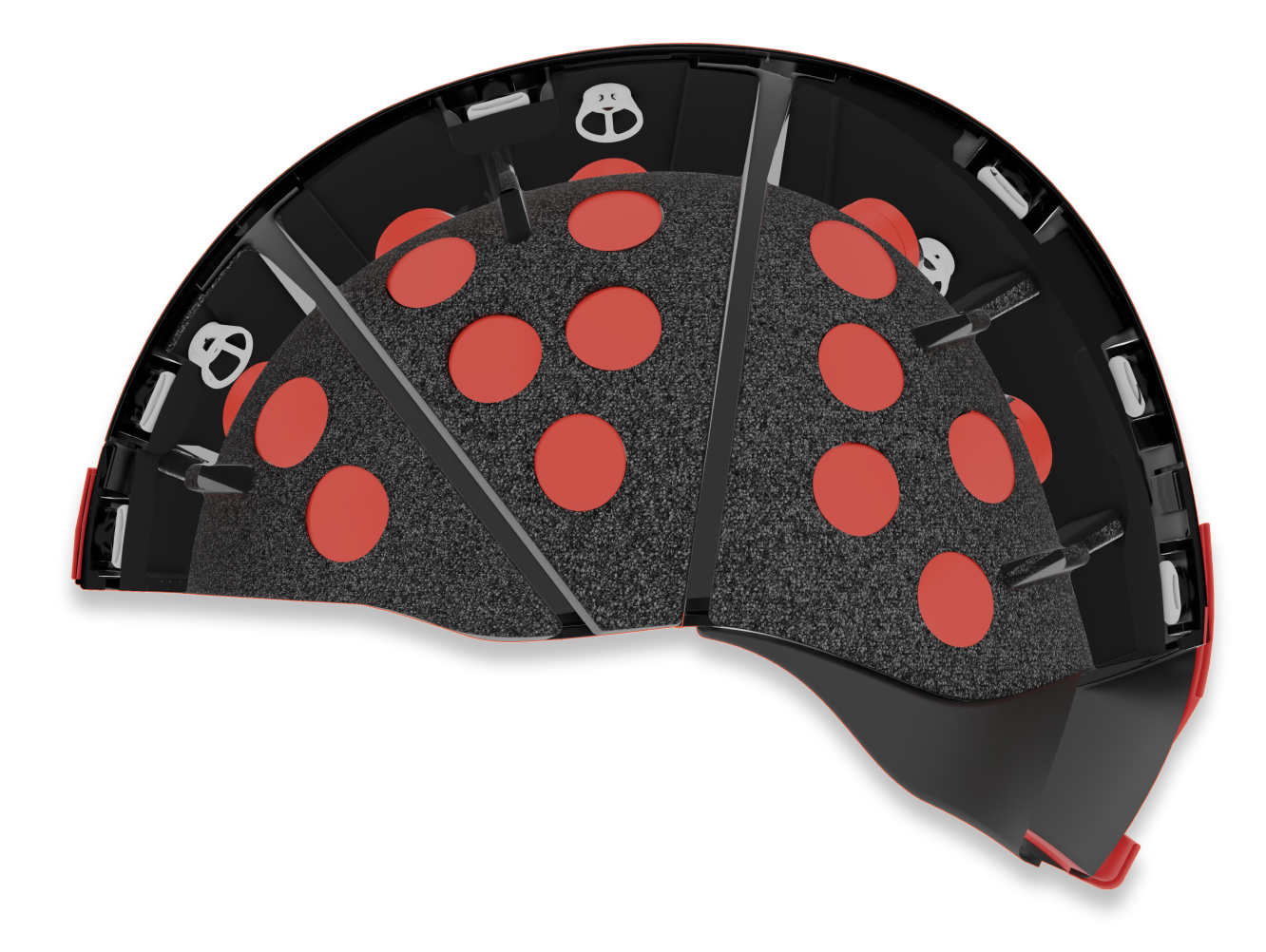

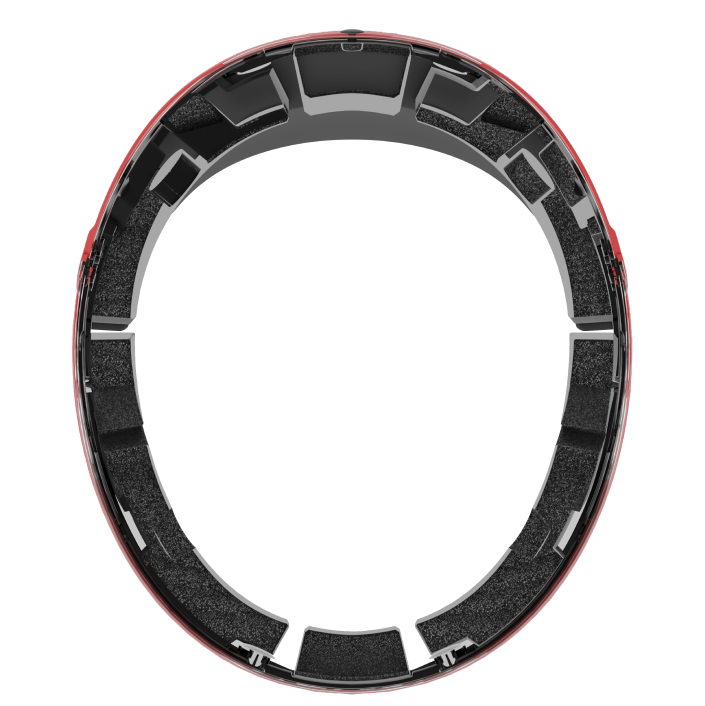

Our Patented

Dynamic Frame

Our 2x patented dynamic frame is designed to articulate in more than 8 different sections to make seamless and natural adjustment to any headshape.

The polycarbonate and ABS blend frame can expand more than 200% laterally and 130% longitudinally to ensure that it fits on every head perfectly.

Behind this lies a novel structure of carbon, rivets and slotted retention plates that enable this movement, while maintaining the ultimate integrity of the unit when you need it most – in an impact.

Our Patented

Dual Stage Liner

A patented composite protection system which utilises multiple materials to absorb more force across a larger range of impacts. We know now that it’s not just the big TBI’s that are problematic for our brain, but also the sub-concussive impacts that cause CTE.

Using a combination of firmer and more docile materials allows the A2 to protect more effectively through it’s depth of compression; softer like a pillow in small impacts and harder like a car’s crumple zone in big hits.

This more progressive impact matrix gives the A2 a broad range of effectiveness on the hill.

The Occipital Cup

The OC is a unique tension and cup system that is designed to assist in cupping one of the most unique points of any head – the Occipital Bump. Located where your spine enters the skull, every bump is different. It represents the area where you’d normally perch a hat or a beanie but is typically left alone by traditional helmets.

We cup this tension member down underneath your occipital bump, causing the entire unit to sit lower, closer and more comfortably to your head. A tester said it ‘feels like a hug’, and that’s the work of the dynamic frame and OC working together seamlessly.

Using our Patented

Non-Newtonian Materials

Our dual-stage liner utilises shear-thickening non-Newtonian PU foams that are naturally soft, but harden instantly in response to impact, delivering a dynamic foam hardness that intelligently protects from small impacts to big hits.

Double Certified.

The Anti Ordinary A2 is certified to and significantly exceeds the EN1077 (European) and ASTM F2040 (USA) helmet certifications standards. Both certifications drop a steel headform from a pre-determined height.

In these tests, we measure the force transmitted to the brain throughout the impact, so less force is better.

As you can see below in our drop test results, we are a lot lower (a lot better) than the standard.

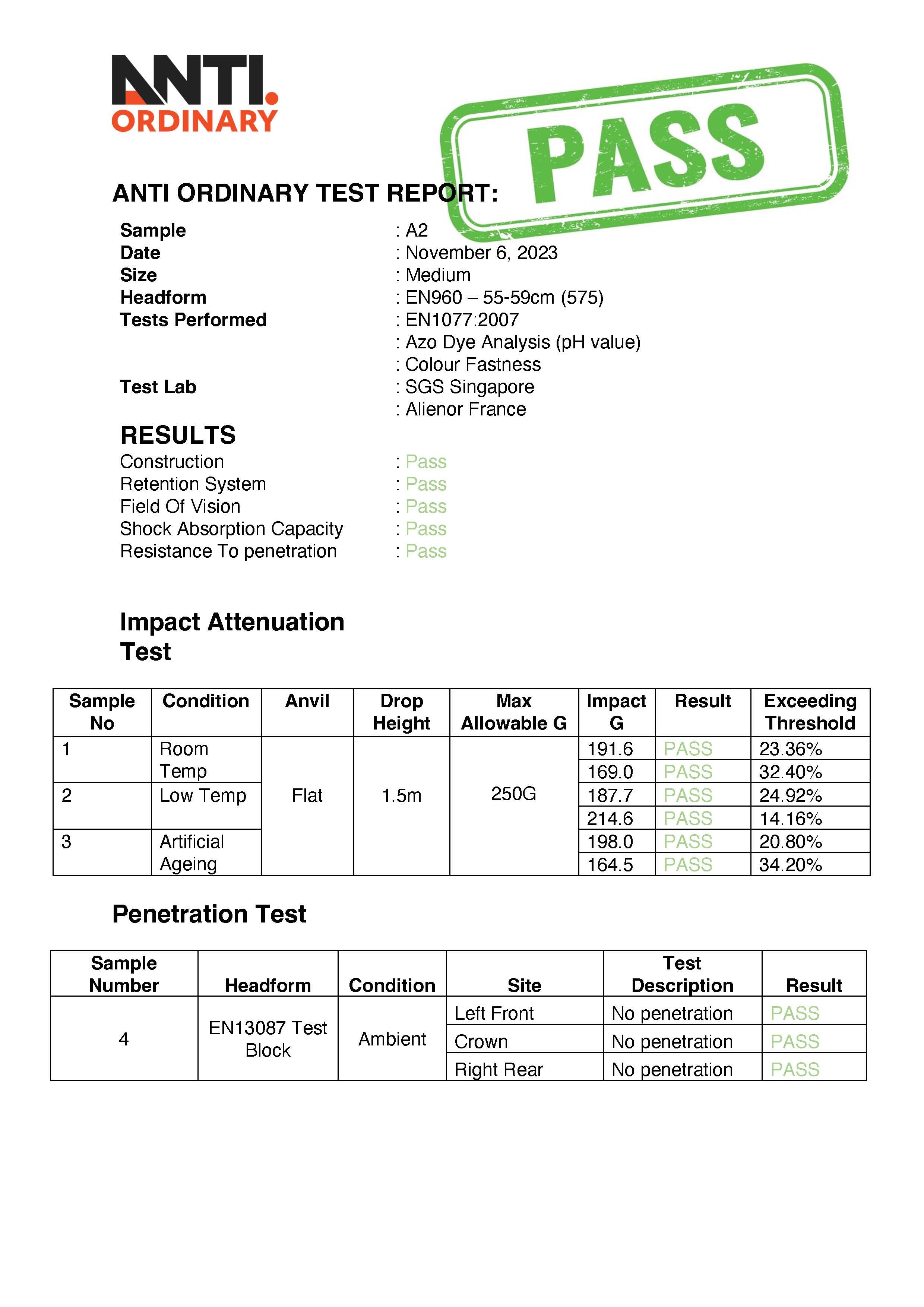

The Test Results.

EN1077 Test results

ASTM F2040 Test Results

EN1077 Certification

The EN1077 drops the metal headform from 1.5m onto a flat anvil, and has a passing threshold of 250G, with 250G being the maximum force that is allowed to be transferred to the brain to pass the standard.

It also does a penetration test, with a metal striker dropped from 37.5cm, where no contact with the headform is allowable.

ASTM F2040 Certification

The ASTM F2040 drops from a variety of heights, ranging from 2m to 1.2m, depending on the drop surface’s shape.

ASTM tests a kerbstone (square), hemisphere (round) and flat anvils.

Now it's time

We Protect you.

Find the A2 Perfectly Suited to your Head and Style: